Haus Olive Extraction & Processing Line; Complete, Like New Condition

Haus Olive Extraction & Processing Line; Complete, Like New Condition

Georgia

Description

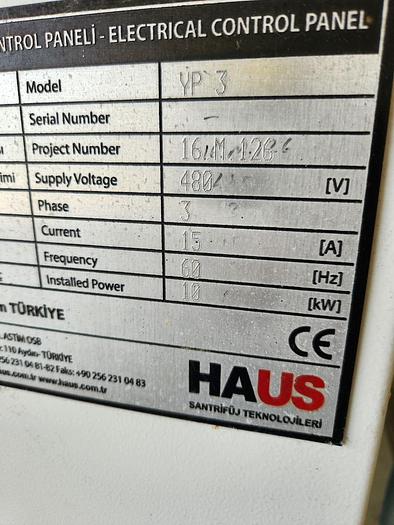

HAUS Continuous Olive Oil Systems is for clearing the harvested olives from foreign matters automatically, to produce quality natural virgin olive oil. Olive pressing is controlled by the central control panel.

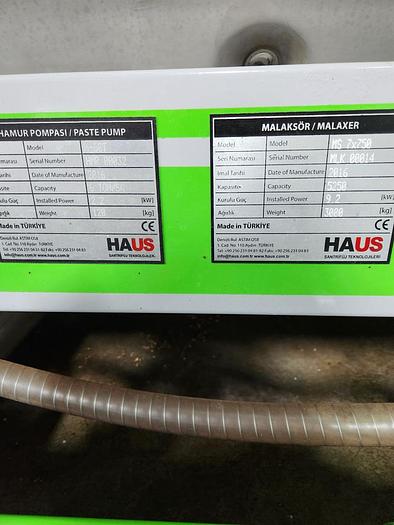

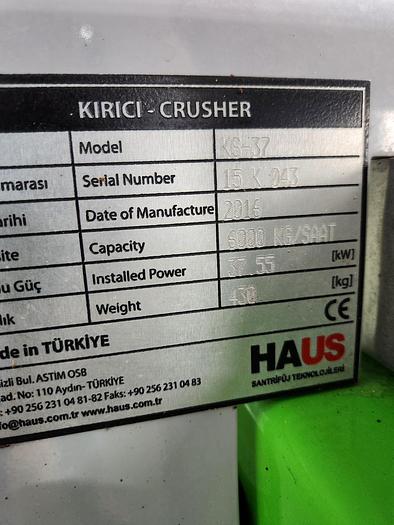

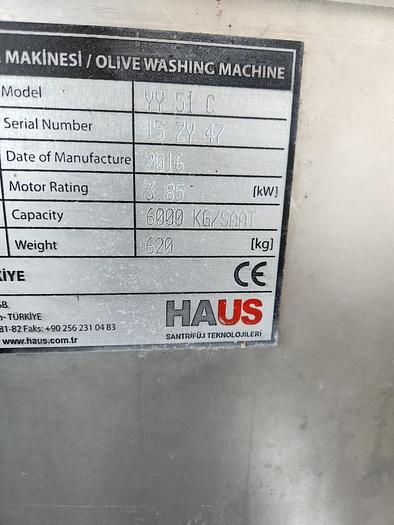

Olives delivered to the plant are unloaded to the olive bunker by the operator/farmer and then conveyed to olive washing machine over the conveyor belt. Separated from their leaves, the olives are washed clean in olive washing machine without causing damage to the fruit. Washed olives fed into Olive Crusher bunker are conveyed to the crushing section through screw conveyor. Olives are crushed in Olive Crusher and semi-paste is obtained. Delivered to Malaxator chambers by screw conveyor or pumps, the semi-paste is kneaded for a period and under conditions specified by the operator in the malaxator and rendered ready for maximal oil extraction. The prepared paste is pumped to the decanter by the paste pump. Water is added under control of flowmeter if required (for 3-phase systems).

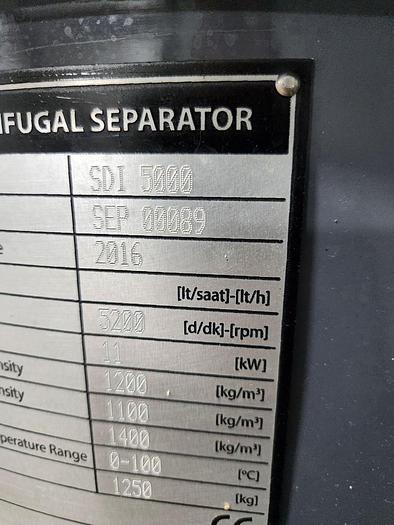

The decanter centrifuge design ensures separation of the incoming olive paste into three phases – oil, solids and water. The olive paste is fed into the bowl through a stationary inlet tube and is then smoothly accelerated by an inlet rotor.

The main application of decanter centrifuges is to separate large amounts of solids from liquids on a continuous basis. They are also used to wash and dry various solids in industry, such as polystyrene beads, clarify liquids and concentrate solids. No storage tanks are available with this system.

Unit was purchased in 2016 but never used. Disassembly, skidding and loading will be additional costs to the buyer. Located in GA.

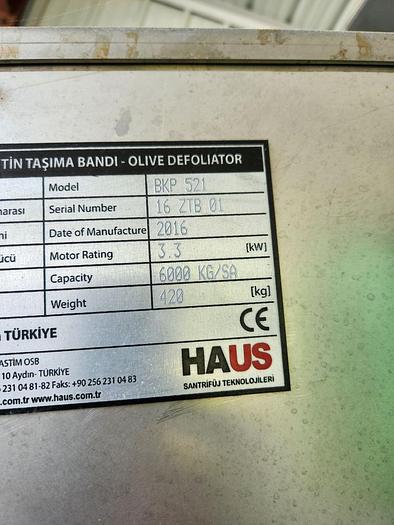

Specifications

| Manufacturer | Haus |

| Year | 2016 |

| Condition | Used |

| Stock Number | 20589 |